For Posterity

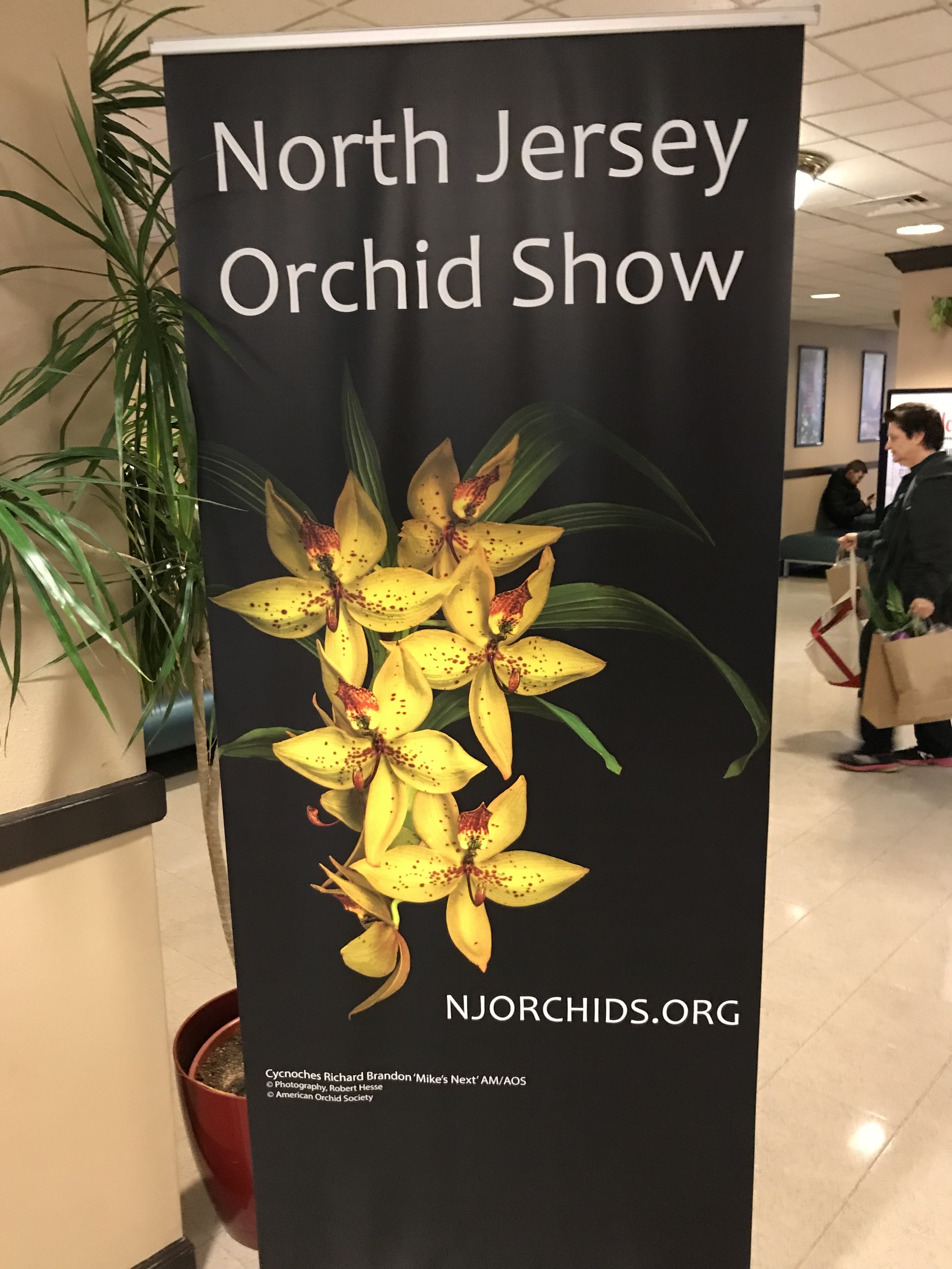

We have been growing orchids for many years. There is a certain excitement, thrill even, when a new plant blooms. For the uninitiated, it is worth pointing out that orchids do not grow quickly, they take years to reach blooming size and we like to buy our plants young since we primarily grow new hybrids. So, hypothetically, imagine buying some baby plants and then you nurture them along for many years, growing them, loving them, potting them up keeping any eye on the temperature through the winter, watching out for pests and then some day, voila, a bloom. A first bloom mind you, many orchids don't come into their own until they have bloomed a few times (read a few more years). Anyways, you get it, orchid blooms = excitement. Well that's the standard, but now imagine when a particularly nice bloom opens up... woohoo, bells whistles etc... We recently had a plant like that, a Dendrobium cross from the venerable Sunset Valley Orchids, Fred Clarke, the proprietor has a magic touch with the little genetic letter game of craps that we growers rely on. Anyways, we digress, so we had this great plant the was on its third blooming and figured, it was worth the 5 hours of driving to show it off at the North Jersey Orchid Show. So, some more background. Orchid names/hybrids are a serious business, the Royal Horticultural Society (RHS) has been keeping track since the 1800's, every cross, every award. In the U.S. we have the American Orchid Society (AOS) which performs the same service/oversight in conjunction with the RHS. If a hybridizer makes a cross then it has to be registered with the AOS/RHS in order to have a name and not be noted as the parent x parent. Often times crosses go unnamed until they have been awarded and shown to be worthy of being recorded for the ages. Now that name is called the grex name (all the thousands of plants with the same parents). The grex name is only part of the story though, because many orchids produce near on 1 million seeds per capsule with near on 1 million variations on how those babies are going to look. With all those variations, if one plant is special it deserves to be recognized, so with orchids each plant or "clone" is viewed individually and once awarded has the right to carry its own name and the initials of the award it won....in perpetuity. So without further ado we present:

Dendrobium Graham Spearman 'Ermela Kaferi' HCC/AOS

The parents of this beauty are Dendrobium Gilleiston Jazz x Brimbank You Beauty - the first plant carried the pod and the second provided the pollen.

The judging process its self was really interesting. The team of judges (it takes 6-7 years to become an accredited judge) reviewed the plant, reviewed the parents and voted regarding the quality of the flowers, the plant and the overall inflorences. They provide their judgements in a blind ballot and the scores have to have a 6 point or less spread, then those numbers are averaged to arrive at the final score which determines the type of award. If the scores have a more than 6 point spread then they have to debate again and if they can't get it down to the range then nothing can happen. Den. Graham Spearman 'Ermela Kaferi' received 79 points which is a very respectable score, especially on a relatively young plant. If the judges come to an agreement on an award the next step is to write a detailed scientific description of the flowers and spike and then the plant is photographed with special attention paid to accurate color rendition. The description and photo are then recorded into the various national databases and the photo is published in the AOS Digest 'Orchids' Magazine along with the grower information and location the award was granted.

Trying to transport the plant without damage was quite difficult and required a fair bit of creativity and slooow driving on wonderful Jersey roads.

All in all this was a very interesting process that every orchid grower should give a try at, worst case you don't receive an award and you come away with heaps of knowledge, best case, your chosen name lives forever in orchid databases and collections. We will most definitely be making more of an effort to show our plants in the future and with the knowledge we have gleaned we will be able to make better choices in what we grow and breed in our own collection.