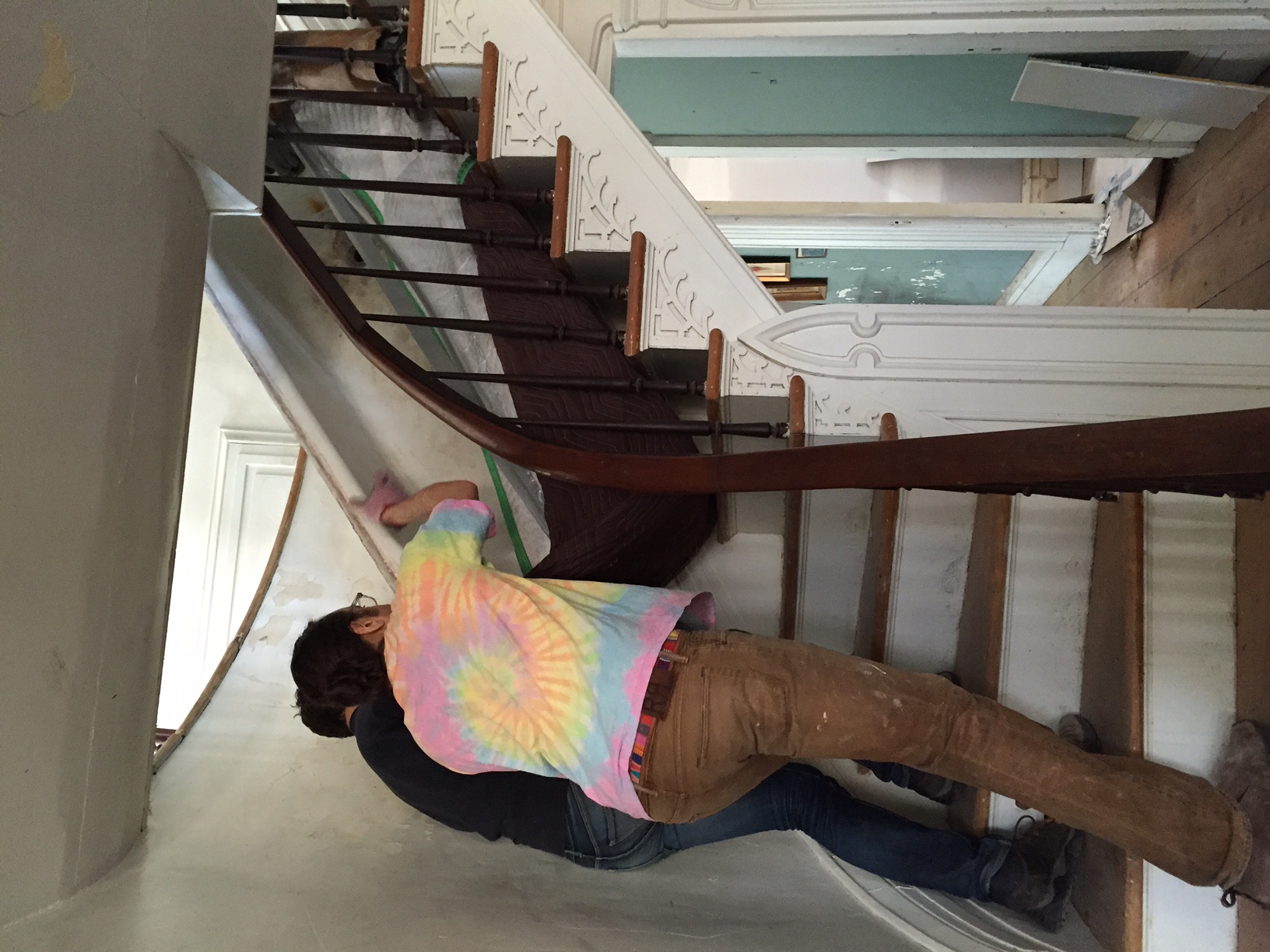

Amenia Bobsled Team

That's the name for our tub removal crew, a big thanks to Dustin Barzell, and Oren Petranker for helping to haul the old castiron beast out of the upstairs hallway. It actually was in the pink bathroom, but the spot it graced for near on 100 years will become a hallway and thus improve the flow immeasurably. Now, we don't know the exact weight on the tub, but Oren and Graham have hauled ovens, coal stoves, butcher blocks etc.. with nary a grunt, but this thing damn near killed the team. Not only was it heavy, it also had to come down a curved staircase without damaging the plaster or railing, not an easy task.

Behold....

It got much easier to move once we realized that the slip nuts on the plumbing had not released, so out came the sawzall and it cut just like buttah'. A special thanks to Julie for documenting the process and doing some solid pre tub removal demolition. Go to our instagram page for a fun video of the final push @brokenchimneyfarm